In the field of producing batteries for electric vehicles, accuracy and productivity are critical. LEAD, a leading name in smart manufacturing companies, has unveiled a groundbreaking solution that is set to redefine the industry. It’s fully automatic whole line integrating 3D pad printing/screen printing and inspection system boasts high-precision visual-guide alignment and AOI automatic inspection, setting a new standard for quality assurance in battery production.

The Power of Camera Test Technology in Electric Car Battery Manufacturing

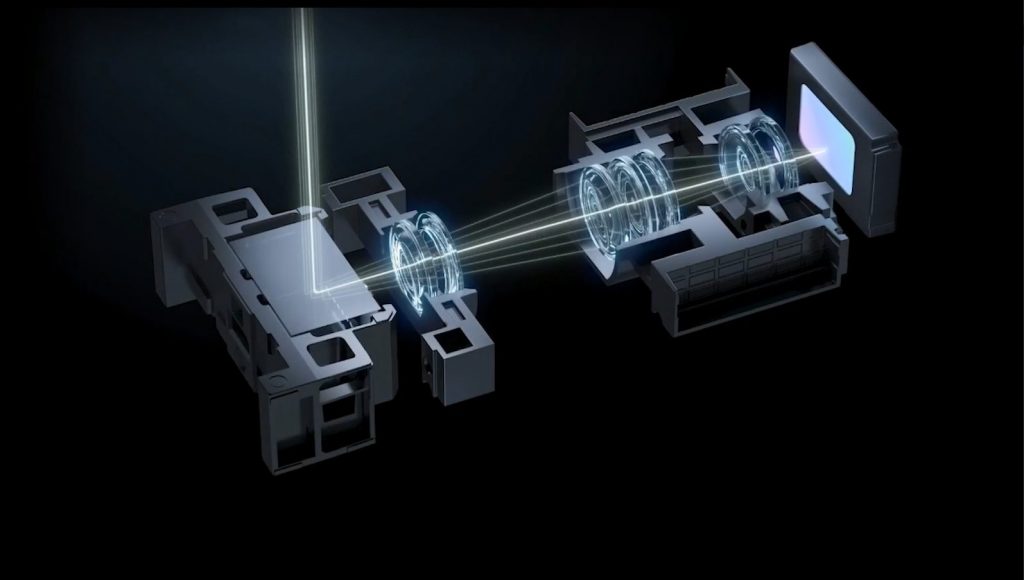

LEAD’s innovative camera test technology plays a pivotal role in enhancing the efficiency and accuracy of electric vehicle processes. By seamlessly integrating 3D pad printing, screen printing, and automated inspection systems, LEAD’s solution ensures that every battery component meets stringent quality standards before assembly.

A Comprehensive Solution for Smart Equipment Production

LEAD isn’t just offering a product — it’s delivering a comprehensive solution for smart equipment production. Its automotive battery production system encompasses everything from battery cell manufacturing to packaging and testing equipment, providing manufacturers with a true one-stop shop for all their production needs.

Conclusion:

With LEAD’s cutting-edge camera test technology and full-line solutions for electric car battery manufacturing, smart manufacturing companies now have access to a game-changing solution that promises to streamline operations and elevate quality standards across the board. LEAD’s commitment to innovation and excellence solidifies its position as a frontrunner in the industry, paving the way for a more efficient and sustainable future in electric car battery production.