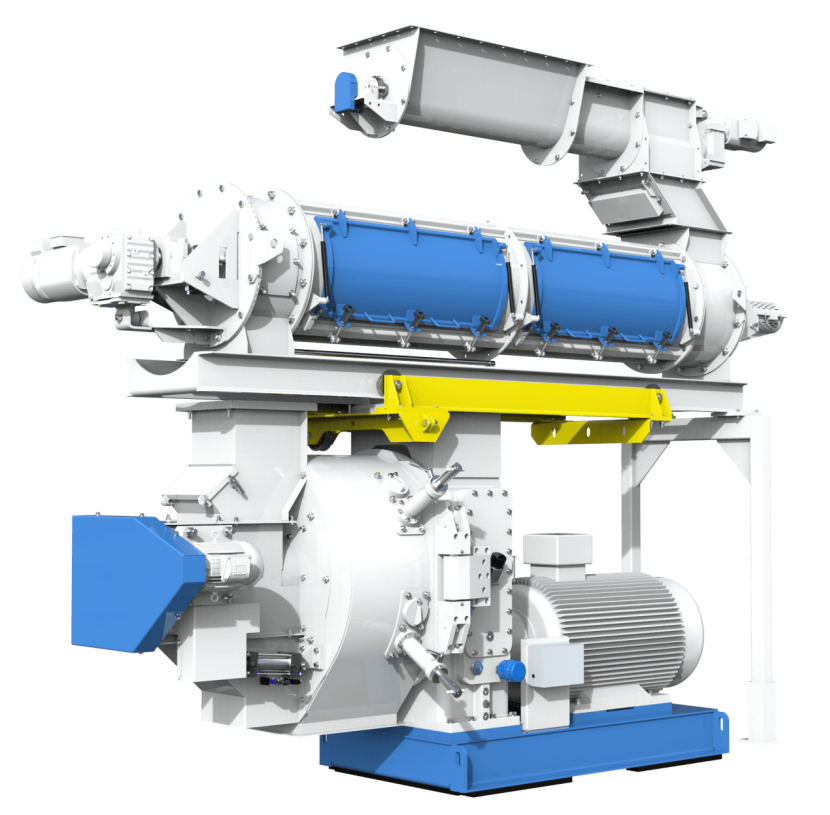

FAMSUN, a major inventor in feed and food engineering machinery, announces its sophisticated KN Series Ruminant Pellet Mill with STZN Conditioner. These devices are designed to enhance production efficiency and fulfill the complicated needs of modern feed processing. Because of FAMSUN‘s dedication to precision engineering, the company is able to guarantee dependable performance, which makes it a viable option for industries that require high-quality machinery.

Efficient Production with Regional and Seasonal Adaptability

The KN Series Ruminant Pellet Mill by FAMSUN is engineered to adapt to regional and seasonal variations in formulas and production modes. This adaptability ensures efficient production of ruminant feed, even under changing conditions. The machine’s robust design handles complex materials, providing consistent output and minimizing operational disruptions.

STZN Conditioner: Enhanced Steam and Liquid Integration

FAMSUN’s STZN Conditioner stands out with its innovative steam addition system. Steam is introduced internally from the rotor, preventing overflow and ensuring complete absorption by the material. Additionally, the external liquid addition system, supported by molasses and two-fluid technology, meets varying liquid requirements. This integration enhances material conditioning, leading to superior pellet quality and production efficiency.

Automation and Forced Feeding Technology

FAMSUN’s feed grinder mixer incorporates advanced automation features, such as automatic lubrication and electric lifting, which significantly reduce labor costs and enhance production efficiency. The application of forced feeding technology and special roll configurations allows for smooth processing of low-bulk-density and complex materials. These features ensure optimal performance and minimal downtime.

High Capacity and Efficiency Gains

With a production capacity of 9-12 tons per hour and hay powder addition ranging from 20% to 40%, FAMSUN’s KN Series Ruminant Pellet Mill delivers an efficiency increase of 15%-20%. This high-capacity output makes it an ideal solution for large-scale operations seeking to maximize productivity while maintaining quality standards.

Conclusion

FAMSUN’s feed grinder mixer and conditioning systems represent the pinnacle of engineering excellence in feed processing machinery. By combining adaptability, advanced automation, and efficient material handling, FAMSUN provides solutions that enhance productivity and reduce operational costs. Choose FAMSUN for reliable, high-performance machinery tailored to meet the demands of modern feed and food engineering.